1、 Direct reduction of initial deviation

This is a basic method widely used in hollow glass processing equipment, that is, after finding out the main deviation factors that affect the processing precision, try to eliminate reduce them.

2、 Deviation compensation method

It is to artificially create a deviation to offset the initial deviation of the process system, use one initial deviation to reduce the other, so as to improve the price precision.

3、 Deviation migration method

The essence of the deviation migration method is to migrate the geometric deviation, support deformation thermal expansion of the process system. For example, when grinding the main control chip of the spindle bearing, the precision of the copper shaft of the cone space the motor shaft is guaranteed by the rotation precision of the lathe spindle, but by the fixture. When the lathe spindle the steel parts are adopted to follow the existing cutting, the initial deviation of the lathe spindle is no longer affected Affect the machining precision, transfer to use fixture to ensure the machining precision.

4、 In situ processing

In the processing assembly line, some precision problems involve many internal relations of parts components, which are relatively complex. If we only improve the precision of parts components to meet the design requirements, it is only difficult, even impossible to achieve. If we use local processing for frequency, we can solve this difficulty.

5、 Deviation sequencing

In the process of processing, because of the existence of the deviation of the rough embryo in the technological process, the processing deviation of this process the change of the deviation of the rough embryo are caused. There are two situations that affect this process: the reflection deviation the positioning deviation. Because the above deviation is very large, the machining precision can be guaranteed, it is economical to improve the precision of the rough embryo process flow. In this case, the deviation sorting method can be used, that is, the size of the rough embryo the previous process can be sorted according to the deviation size, the deviation of a group of rough embryos will be smaller, then the relative position of the game props the steel parts the positioning circle can be adjusted according to each group Arc can greatly reduce the size dispersion range of the whole batch of steel parts, which is suitable for use in places with high precision.

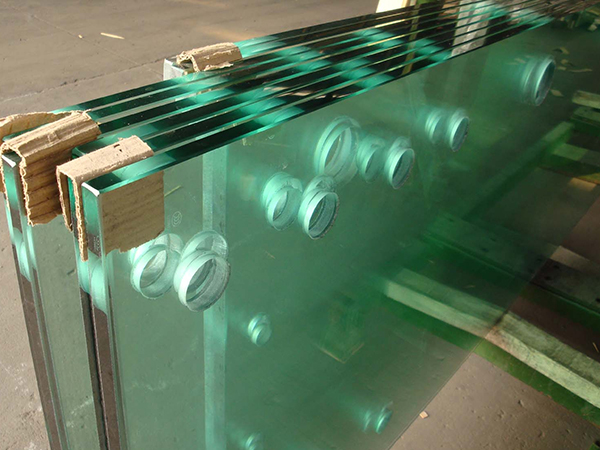

Hollow glass

6、 Deviation average method

It is a method that is conducive to the direct comparison adjustment of closely related surfaces, to the processing of standards between them, so as to achieve a high processing precision.

The above methods are about the processing precision of the hollow glass processing equipment to improve the countermeasures, I hope to help you.

Functional characteristics: pneumatic two-component sealant applicator is a kind of sealant applicator for hollow glass, which is produced with excellent technology all over the world. A multi-component pump B multi-component pump are respectively driven by pneumatic system controlled by contactless home appliance automatic control system. The reversing is smart reliable. Its unique convenient adjustable dispensing mechanism ensures the two-component sealant with large bottom limit Nearly strict preparation requirements, continuous even dispensing, good dispensing effect, fast production speed.