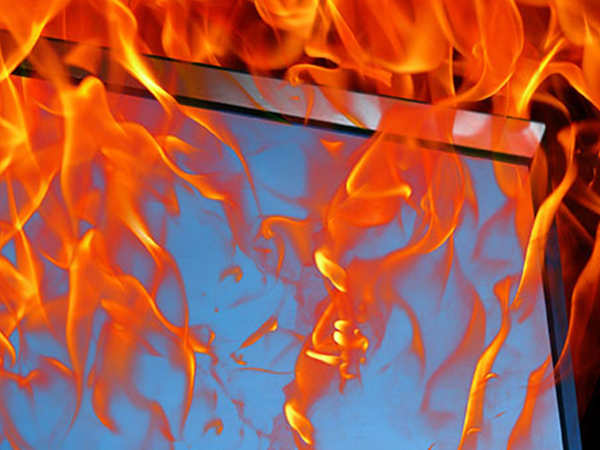

The fireproof glass is composed of two layers of glass flame retardant, surrounded by a layer of sealant a layer of splash proof layer. So how to make the fireproof liquid for pouring the fireproof glass? Let's have a look.

The optimal chemical tempering method is adopted for the glass layer. By using a new type of tempering agent containing cerium, the exchange rate of sodium potassium ions in the glass is increased, the depth of the stress layer is increased to 40-90um.

The flame-retardant layer is made of the formula added with nano silver particles, its components are calculated by weight percentage: sodium dihydrogen phosphate 3 ~ 5, sodium tetraborate 5 ~ 7, epoxy phenolic resin 40 ~ 42 modified by original ethyl silicate. Brominated phthalic acid anhydrous acid 20-22, diphenol A epoxy resin 15-17, polyamide 8-10, mixed coupling agent 5-7, nano silver 2-4.

The preparation process of the fireproof liquid is: weighing sodium dihydrogen phosphate, sodium tetraborate, epoxy phenolic resin modified by original ethyl silicate, brominated o-phenylanhydrous acid, diphenol A epoxy resin, polyamide, nanometer. The silver sol was added to a certain amount of deionized water stirred for 30 minutes at 2000 rpm; the TEOS modified epoxy phenolic resin was added to the solution stirred for at least 1 hour at 5000-6000r / min; the silane coupling agent was added stirred for 1 hour at 2000r / min; the stirred solution was filtered with a 300-400 mesh screen, the filtrate was a fireproof solution.

Quantitative inclined pouring process is adopted for the fire liquid, the process flow is as follows:

First, according to the size requirements, the toughened glass is cut trimmed, then the glass to be spliced is washed dried, the inner surface of the glass is treated with silane coupling agent KH570; the glass gasket is coated with uniform special silicone rubber, which is bonded with the inner surface of the treated glass, the periphery is sealed with flame-retardant structural adhesive; The grouting port (usually 20-25mm in the long side direction) is left on the glass gasket for grouting, the liquid is poured into the cavity with fireproof glue, which is fully solidified, then sealed sealed.