1、 How to distinguish toughened glass ordinary glass?

Look at the glass sign

To see if there is a 3C mark for toughening on the edge of the glass, the 3C mark (the kind that can't be scraped off) is basically toughened glass. The processing procedure of toughened glass is to cut the float glass of common float glass into the required size first, then grind the edge, clean mark the CCC Mark with ink. The glass after being fired in the toughening furnace cannot be cut processed. ink through the high temperature after the general situation is scraped off. If the 3C mark on your glass can be wiped off by hand, it can be concluded that it is fake toughened glass.

Check for slight deformation

the side to see whether the glass has slight deformation, because the glass will have slight deformation after being fired at high temperature, which can only be seen the side of the glass, the front is generally easy to see.

Look at the pieces of glass

After the ordinary glass is broken, it is large sharp, easy to hurt people. After the toughened glass is broken, it is granular, with blunt edges corners, which is easy to hurt people.

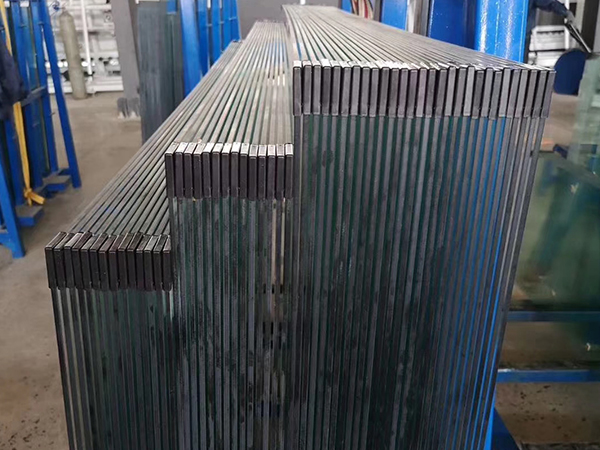

2、 Toughened glass is divided into: generally, the thickness of plane toughened glass curved toughened glass is 4, 5, 6, 8, 10, 12, 15 19mm; the thickness of curved toughened glass is 5, 6, 8 10 mm.

3、 Toughened glass can be divided into physical toughened glass chemical toughened physical toughened glass. Ordinary flat glass float glass are processed by quenching air-cooled quenching under specific process conditions. Chemically toughened glass is a kind of processing method, which changes the surface molecules of ordinary flat glass float glass by means of ion exchange, forms a layer of compressive stress layer on the surface of glass.

4、 Characteristics of toughened glass:

High impact strength

It is 4-5 times higher than ordinary glass, 5 times higher than ordinary flat glass, with high bending strength, good thermal stability, can withstand the temperature difference of 200 ℃; it is bright clean, transparent, can be cut. In case of super impact damage, the fragments are scattered small particles without sharp edges corners.

After tempering, the thickness will be slightly thinner. The reason for the thinning is that after the glass is softened by hot melting, it is cooled rapidly by strong wind force, which makes the crystal gap inside the glass smaller the pressure larger. Therefore, the glass is thinner after tempering than before tempering. Generally, 4-6mm glass thins 0.2-0.8mm after tempering, 8-19mm glass thins 0.9-1.8mm after tempering. The degree of detail depends on the equipment.