Toughened glass

Characteristic safety

When the glass is damaged by external force, the fragments will form small blunt angle broken particles similar to honeycomb, which is easy to cause serious injury to human body.

high strength

The impact strength of toughened glass with the same thickness is 3-5 times that of ordinary glass, the bending strength is 3-5 times that of ordinary glass.

thermal stability

Toughened glass has good thermal stability. It can bear three times of the temperature difference of ordinary glass can bear 300 ℃ temperature difference.

Advantage

First, the strength is several times higher than the ordinary glass, bending resistance.

The second is the safety of use, the increase of its bearing capacity improves the fragile nature, even if the toughened glass is damaged, it also presents small pieces without sharp angle, which greatly reduces the harm to human body. The properties of toughened glass are 3-5 times higher than that of ordinary glass, which can bear the temperature difference of more than 250 degrees, which has obvious effect on preventing thermal cracking. It's one of the safety glasses. In order to ensure the safety of high-rise buildings with qualified materials.

shortcoming

Disadvantages of toughened glass:

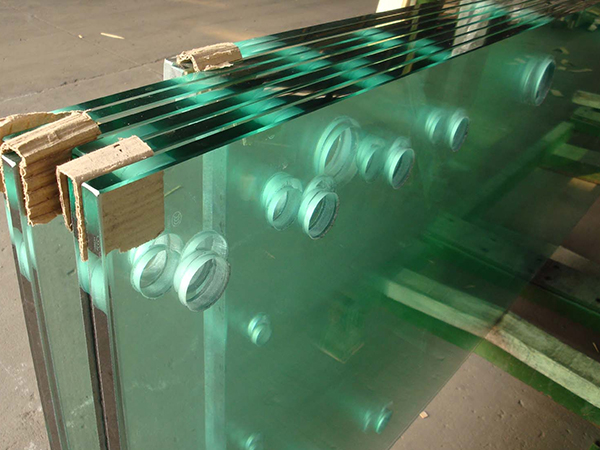

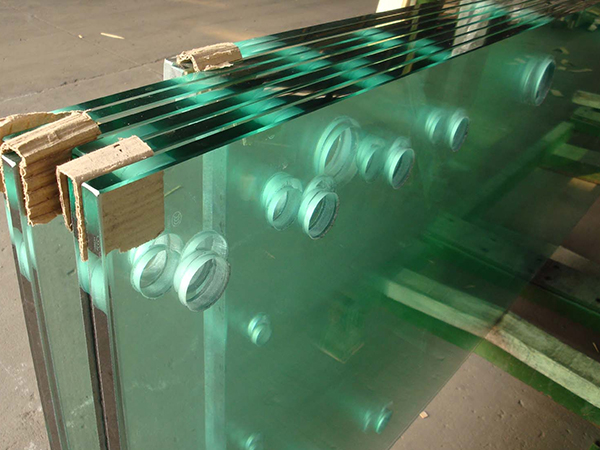

1. The toughened glass can't be cut processed any more. It can only be processed to the required shape before toughening, then toughened.

2. Although the strength of toughened glass is stronger than that of ordinary glass, toughened glass has the possibility of self explosion (self rupture), while ordinary glass does have the possibility of self explosion.

3. The surface of toughened glass will be uneven (wind spots), with slight thickness thinning. The reason for the thinning is that after the glass is melted softened, it is cooled rapidly by strong wind force, which makes the crystal gap inside the glass smaller the pressure larger, so the glass is thinner after tempering than before. In general, 4-6mm glass becomes thinner 0 after tempering. 2-0. 8mm, 8-20mm glass thinned 0 after tempering. 9-1. 8MM. The specific degree shall be determined according to the equipment, which is also the reason why toughened glass cannot be used as mirror.

4. The flat glass used in building after tempering furnace (physical tempering) generally has deformation, the degree of deformation is determined by the process of equipment technical personnel. To some extent, it affects the decoration effect (except for special needs).