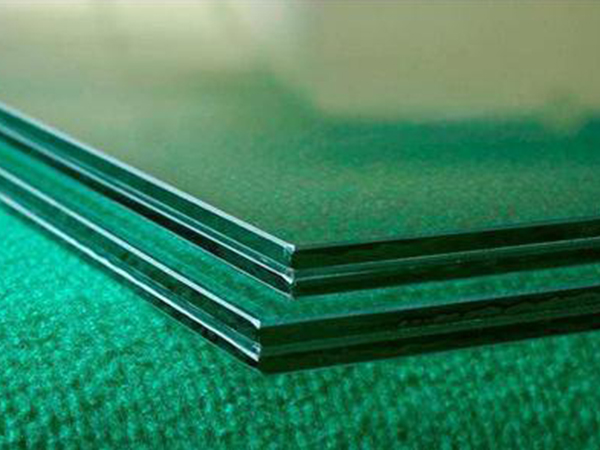

Laminated glass is a composite glass product consisting of two more pieces of glass sandwiched with one more layers of organic polymer intermediate film. After special high-temperature pre pressing ( vacuuming) high-temperature high-pressure processing, the glass intermediate film are permanently bonded as a whole.

The commonly used laminated glass intermediate films are: PVB, SGP, EVA, PU, etc.

Five characteristics

1. Safety: in case of external impact, because the elastic intermediate layer has the effect of absorbing impact, it can prevent the impactor penetrating. Even if the glass is damaged, it will only produce fine cracks similar to spider network. Its fragments are firmly adhered to the intermediate layer will fall off hurt people. It can be used until it is replaced.

2. Anti theft: PVB laminated glass is very tough. Even if the thief knocks the glass, the middle layer the glass are firmly adhered together, the integrity is still maintained, so that the thief cannot enter the room. After the installation of laminated glass, the guardrail can be saved, which can save money beauty get rid of the feeling of cage.

3. Sound insulation: due to the damping function of PVB film to sound waves, PVB laminated glass can effectively inhibit the propagation of noise, especially for buildings located at airports, stations, downtown areas on both sides of the road after the installation of laminated glass, the sound insulation effect is very obvious.

4. UV protection performance: PVB film can absorb more than 99% UV, thus protecting indoor furniture, plastic products, textiles, carpets, works of art, ancient cultural relics commodities fading aging caused by UV radiation.

5. Energy saving: the laminated glass made of PVB film can effectively reduce the sunlight transmission. With the same thickness, the laminated glass made of PVB film with dark color low light transmittance has a stronger ability to block heat. At present, laminated glass produced in China has many colors.